Rohm and Haas chooses batch process development tool

Contents:

Slashing Development Time

Steering BDK

BDK Update

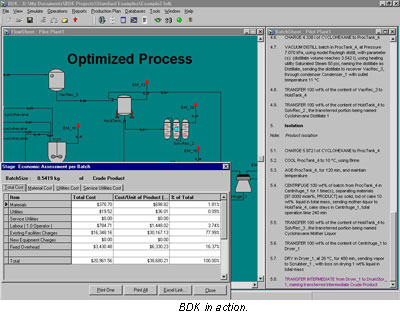

Rohm and Haas Co. (Philadelphia, PA) has signed a corporate-wide agreement with Hyprotech Ltd. (Calgary, AB, Canada) for several network licenses of BDK batch processing lifecycle software. Rohm and Haas will also become a founding member of a steering group that will guide the future technical direction of BDK.

BDK provides process development and information tools that enable batch chemical producers to shorten development cycles, accelerate time-to-market, and reduce development and manufacturing costs.

On the process side, BDK decision-support tools help users optimize chemical synthesis, reaction engineering, and such batch unit operations as crystallization, solid-liquid separation, and drying. Equally important, BDK transfers documentation throughout the project to support regulatory compliance

Slashing development time

"BDK has enabled Rohm and Haas to increase productivity, improve process robustness and enhance decision-making," says Rohm and Haas senior manager Frank Lipiecki. "The overall effect has been up to an 80% reduction in development and modeling time where BDK was employed, compared to using spreadsheets and other conventional tools."

"For the batch processing industry, process development and scale-up are critical," adds Rohm and Haas Technical Fellow Alan Leviton. "During this time, rapid generation of alternatives can have a real impact on the overall development path, offering significant opportunities to avoid scale-up problems and reduce process development time.

"BDK is a unique tool that will enable our chemists and engineers to share critical process information quickly and easily, enabling a review of possible options earlier in the work process to help identify the best candidates for further evaluation," Leviton concludes.

According to Hyprotech CEO Wayne Sim, BDK provides benefits that go beyond initial project development. "BDK is a true lifecycle solution that enables batch processing companies to maintain and grow their competitive advantage," says Sim.

"With BDK, chemists can concentrate on selecting and optimizing chemistry, and engineers can concentrate on recipe optimization, scale-up and equipment allocation. BDK seamlessly transfers process information and can automatically generate corporate reports, thus providing significant strategic benefit," he explains.

Steering BDK

Rohm and Haas has also become a founding member of the new BDK Steering Group, which will guide the product's future technical development.

"In addition to the substantial feedback from the BDK Steering Group, BDK continues to incorporate the proven batch industry experience and leading edge technology," says Hyprotech batch processing business manager James McGill. "This, combined with our alliances with GSE Systems (BatchCAD) and VisiMix, strongly underscores our continuing focus to provide a total solution for all stages of batch process development and design."

BDK is a component of Hyprotech's integrated Basys batch processing suite. Basys combines software tools, in-depth process knowledge, and layered models to enhance overall business performance. In addition to BDK, Basys includes BatchCAD (reaction kinetics and batch reactor modeling), VisiMix (mathematical modeling of laminar and turbulent mixing processes), SPS Process Manuals (comprehensive knowledge bases on separation technologies), and Process Consultancy (specialists to provide in- depth process expertise).

BDK update

Hyprotech recently updated BDK 2000 to version 3.1. According to McGill, the new version provides additional features to enable users to modify BDK components, incorporate their own reports and models, and share project information online.

Among the enhancements:

- Information Sharing. BDK enables users to document and share project data through an online repository that supports versioning, project check-in/check-out, and locks. V3.1 provides added support for the Microsoft Database Engine (MSDE), a freely distributed database engine compatible with SQL Server.

- Add-Ins. Users can add new functionality directly to BDK, including custom reports, links to other tools, and custom interfaces.

- Extensions. Users can incorporate custom models directly into BDK using spreadsheets, Visual Basic script, or ActiveX components. The updated interface in v3.1 provides greater flexibility.

- Add-In/Extension Wizard. Guides the user through the process of creating add-ins and custom reports. It also simplifies the incorporation of add-ins and models into BDK.

- BatchCAD Link. A link to GSE System's BatchCAD has been added to the "React" operation in BDK and as a custom model.

- Recipe Bill of Materials. V3.1 automatically synchronizes the process chemistry and recipe.

- Emissions. Generate reports for hazardous air pollutants (HAPs) or other regulated components. EPA 1999 added as well as various updates and enhancements.

Hyprotech is a member of the AEA Technology plc group of companies. In addition to Basys, it also produces Hysys continuous process simulation software and Axsys plant lifecycle data management software.

For more information: James McGill, Hyprotech, Ltd., 707 8th Avenue SW, Suite 800, Calgary, AB, Canada T2P 1H5. Phone: 403- 520-6092. Fax: 403-520-6060.

Edited by Alan S. Brown

Managing Editor, Chemical Online

For the latest chemical industry news, products, and technology, subscribe to Chemical Online's free biweekly e-mail update.