Pulsair mixer offers thorough mixing at high efficiency

By Richard Carranza,

Editor/Consultant, Lisle, IL.

The patented Pulsair mixer is truly a remarkable piece of equipment. The mixer can completely mix and agitate a vessel with absolutely no moving parts. The mixing is completed solely through the injection of air bubbles.

Principle of Operation

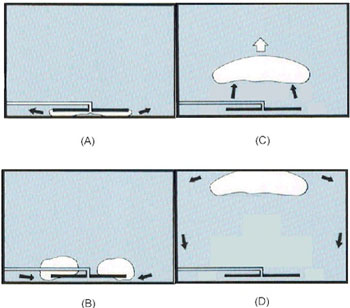

The Pulsair mixer only uses air bubbles to achieve its mixing goals. As can be seen in Figure 1, panel (A), a single bubble is introduced into the tank via an accumulator plate. The bubble then starts to rise due to its buoyancy, see panel (B).

As the bubble starts to rise, the updraft pulls the liquid and solids, located at the tank bottom, upward. The updraft causes a vacuum below it. The void is filled with liquid that moves from above the bubble, around its edges, and down to the tank bottom. This is shown clearly in Panel (D).

The precise timing of the air bubble injection is critical. Typically, only one bubble is ever above the accumulator at a specific time. When a very large tank is being mixed, then several strategically located accumulator plates are used simultaneously.

Applications

One of the great aspects of the Pulsair mixer is that it can fit into almost any space. Most mixing applications are strongly defined by impeller diameters, baffle spacing, etc. The Pulsair mixer; however, with its compact accumulator plate, can be retrofitted into almost any design.

- Lube Oil Mixing - the accumulator is placed below the heater coils. Thus, the oil is pulled through the coils. Forced convection supercedes natural convection and the heating time is greatly reduced.

- Slurries - the mixing system is an excellent choice of slurries, because the updraft caused by the liquid pulls the settled solids back up into the bulk of the fluid. Successful slurry applications include pigment and lime mixing.

- Wastewater - aside from excellent mixing, the Pulsair mixer also aides in the aeration of wastewater. Though some aeration is still needed, less is required due to the effectiveness of the mixing system.

Additional Benefits

In addition to the benefits already mentioned, the Pulsair mixer offers even more advantages:

- the cost of the Pulsair system is normally 20% to 80% lower than that of traditional mechanical systems.

- multiple tanks with multiple accumulators can be controlled from a single programmable controller.

- since the system uses no moving parts, the energy savings can be as high as 80% relative to mechanical systems.

Dick Parks, President, Pulsair Systems, Bellevue, WA, says, "Pulsair is the only mixing technology that is new to the mixing industry. It is simple, effective, and can mix a tank of liquid quickly because it involves the entire contents of the tank in seconds."

For more information contact Pulsair Systems, 1940 124th Ave, NE, Bellevue, WA 98005. TEL 425.455.1263 FAX 425.451.7312.

Subscribe to our free e-mail newsletter.

Click for a free Buyer's Guide listing.