Packings Outperform Trays in Sour Gas Treatment

Process details

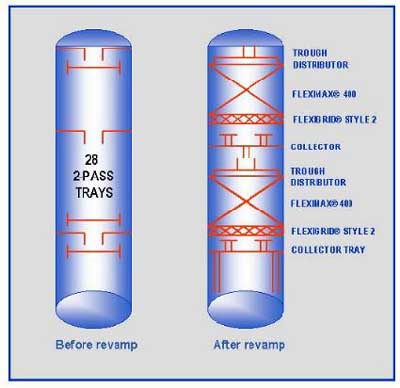

Sour gas is treated in two, parallel, 2550-mm-dia. absorbers to remove CO2 to a level of 25 ppm(v) maximum. The total flowrates vary from 290,000 m3/h to as much as 600,000 m3/h and the feed CO2 ranges from 3.67 to 1.73 mol%. The original design installed 28 valve-type trays, spaced at 450 mm in each column.

Working hand-in-hand with the customer, Koch-Glitsch performed detailed column scanning and determined that operational problems including foaming were seriously affecting both the capacity and the CO2 removal efficiency. Koch-Glitsch recommended that the columns be revamped with packing. A detailed process study was performed to determine the most cost-effective revamp solution. The study simulated operating data and required conditions, taking into account the customer's need for operational flexibility.

Two packing types

The existing trays were removed and replaced with two sections (each 3.62 m high) of Koch-Glitsch Fleximax high-efficiency random packing to provide the required number of theoretical stages. This packing has a unique geometry that provides excellent radial spreading combined with superior mechanical integrity. This high performance packing makes deep beds possible without packing deformation.

The packing is supported by two layers of Koch-Glitsch Flexigrid packing to minimize rich-amine retention time and reduce the risk of foaming. This second material is a structured packing designed to maximize capacity and minimize pressure drop.

The Koch-Glitsch solution required no welding on the vessels, minimizing downtime. Excellent coordination between customer and supplier resulted in flawless execution of the revamp.

The absorbers were started up after revamp and easily met design requirements. Effective partnering between client and supplier from beginning to end of this project resulted in a successful revamp with performance exceeding requirements.

Edited by Nick Basta

For more information: Koch-Glitsch, Inc. 8285 El Rio, Suite 130, Houston, Texas 77054, USA. Tel: (713) 747-3330, fax: 713 747-3320.

For related material, visit the Koch-Glitsch Mixing & Reaction Technology storefront.