New Urea-to-Ammonia Route Simplifies NOx Reduction

Under the agreement, says Thermatrix chairman John T. Schofield, both companies will jointly market the system. Hamon Research-Cottrell will provide engineering services, while Thermatrix manufactures the equipment. Thermatrix also manufactures SCR and SNCR systems.

Potential users include utilities and chemical producers, particularly those in Houston and other regions with high NOx pollution. Thermatrix also plans to integrate the technology into a diesel pollution-reduction system capable of addressing particulates, hydrocarbons, and carbon monoxide, as well as NOx.

The companies say the US Patent Office has allowed a patent for the technology and should issue it shortly. EC&C developed the process with funding from an EPA Small Business Innovation Research (SBIR) grant.

Ammonia vs Urea

"This technology combines the process advantages of an ammonia injection system with the safer storage and handling characteristics of a urea based system," says Schofield.

"There are two methods used to reduce NOx with ammonia," he explains. "One camp uses urea because it's safer to handle and store. Its disadvantage is that it requires a higher temperature to form ammonia. That means you have to inject it directly into the boiler under very carefully controlled conditions.

"Ammonia," he continues, "can be injected downstream from the boiler for maximum impact. That makes it more efficient. But ammonia is more difficult to store. It's a liquefied gas, so you have to keep it chilled." In addition, EPA has classified both anhydrous and aqueous ammonia at concentrations down to 20% as a regulated toxic substance.

"The U2A process combines the advantages of urea storage and handling with the efficiency of ammonia injection," says Schofield. It permits companies to transport, handle, and store urea, yet inject ammonia downstream of the boiler for improved efficiency. "We believe it will be highly cost-competitive because it's so expensive and complex to inject urea into a boiler," he says.

According to Schofield, Thermatrix's Wahlco division is the nation's largest supplier of ammonia-based NOx reduction systems. By packaging EC&C's U2A technology with its SCR and SNCR systems, he explains, Thermatrix will provide a complete solution that lowers cost, improves safety, lower cost, and enhances reliability and control.

U2A

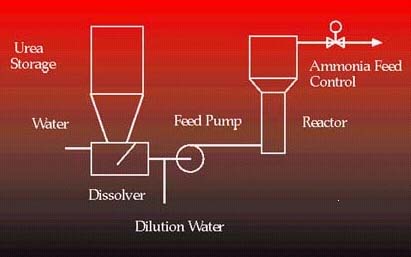

U2A technology uses pressure and heat to hydrolyze urea solutions to produce ammonia. It uses only urea and water. According to developer EC&C, the process is automated, easy to control, and capable of replacing existing ammonia supply systems.

The U2A process starts with dry urea, which is dissolved in water. The resulting aqueous solution feeds into an inline reactor, where it is heated to generate a gaseous mixture of ammonia, carbon dioxide, and water. Controlling temperature and pressure maintains a constant gas supply pressure.

The process requires no storage of ammonia, except for the small amount in the reactor. Even then, it is at an active concentration of less than 2%, far less than the 30% concentration found in commercial aqueous ammonia. EC&C says the company is cost- competitive with aqueous ammonia, and scalable to meet a variety of needs.

Thermatrix provides air pollution control technologies for the chemical, refining, power, pharmaceutical, steel, pulp and paper, and process industries. In addition to ammonia-based NOx reduction systems, the company is a pioneer in flameless thermal oxidation technology.

For more information: John T. Schofield, Chairman, Thermatrix Inc., 308 North Peters Rd, Suite 100, Knoxville, TN 37922. Phone: 423- 539-9603. Fax: 423-539-9643.

Or: EC&C Technologies, 4234 Chevy Chase Dr., LaCanada-Flintridge, CA 91011. Phone: 818-790-7933. Fax: 818-952-8815.

By Alan S. Brown