ICI Chlor-Chemicals Approves Fluor Daniel For BiChlor Chloralkali Technology

"BiChlor moves technology forward by making a vast number of important improvements compared to existing types of bipolar electrolyzers currently on the market," says ICI Electrochemical Technology Business (ETB) business manager Adrian Tattersall. According to ICI, the new electrolytic cells use less power and last longer than other bipolar systems.

"Among the biggest benefits to customers is that the BiChlor technology promises lifecycle cost savings for the new, large- capacity plants," says Fluor Daniel process technology VP Mag Fouad. He says the cells can go into new plants or replace cells that are near the end of their service life, environmentally noncompliant, or that produce low-quality caustic soda.

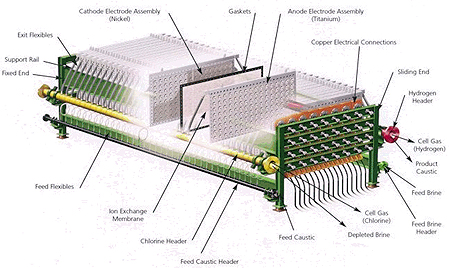

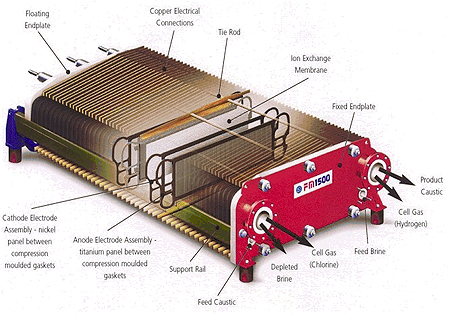

BiChlor

Introduced last summer, BiChlor cells are optimized for large (50,000 mt/yr or greater) manufacturers. Like other bipolar cells, their combination of higher cell voltages and lower currents allow producers to use less expensive rectifiers and electrical components.

BiChlor reduces costs and maintenance in a number of ways. It uses nickel cathodes and titanium anodes to minimize ohmic losses, and bolsters efficiency by operating without any gap between the membrane and its support. The design enhances uniform internal electrolyte mixing and distribution of current. BiChlor's fully flooded membranes reduce membrane embrittlement issues.

BiChlor also promises more uniform electrolyte pH, temperature, and concentration, as well as virtual elimination of stray currents. It uses a simple electrical contact system, and achieves very uniform current distribution.

The unit consumes about 2200 kWh/mt of caustic soda, operating at less than 3.2 V and 6 kA/m2 current density. This is similar to competitive cells. BiChlor, however, is capable of operating at current densities up to 33% greater (8 kA/m2), enabling it to take advantage of next-generation membranes.

For more information: Bill Snyder, Director, Process Technology, Chemical and Life Sciences, Fluor Daniel Corp., 100 Fluor Daniel Dr., C105R, Greenville, SC 29607. Phone: 864-281-4425. Fax: 864-676-7211.

By Alan S. Brown