Gensym Enhances G2 Fermentation Expert

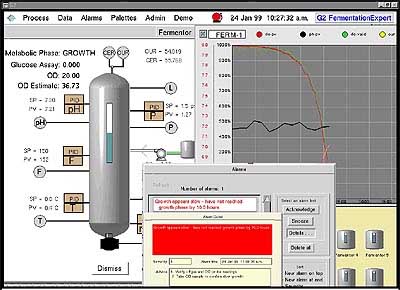

That makes fermentation control units more of a mainstream chemical industry subject. Gensym Corp. (Cambridge, MA), which specializes in operations management software and services, has released G2 Fermentation Expert 2.0, expert system software targeted to the pharmaceutical, food, and beverage industries. By offering several distinct artificial intelligence modules for advanced modeling and control, G2 Fermentation Expert helps increase yields and reduce variability of fermentation processes.

"Fermentation is a difficult process to control due to the variability of raw materials, cultures, and process conditions," said Bob Moore, Gensym's president. "This variability can adversely affect quality and yields and lead to additional processing, schedule disruptions, and lost production. Fermentation Expert helps maintain high levels of quality and yields by utilizing process measurements, historical data and intelligent software technologies to provide operators with real-time analysis of fermentation processes."

"G2 Fermentation Expert reasons reason about fermentation data, just as a human operator would," said marketing communications manager David Siegal. "A fair amount of reasoning has to take place before [G2] reaches its conclusion. For example, it may look at rates of change in the growth of organisms, comparing them against specified rates based on human expertise. So instead of saying ‘growth is slow' the program says ‘growth appears slow.' It then tells you what you need to do to correct the situation.

A major upgrade in the G2 version of Fermentation Expert is inclusion of Neuronline Studio, a product Gensym introduced last year. Neuronline Studio takes historical data and current values, allowing users to work offline. For example, Neuronline Studio can be used to validate "soft" sensors – software constructs that take tangible online measurements of, say, pH and turbidity, and spit out values for difficult-to-measure variables such as cell density.

G2 Fermentation Expert 2.0 is typically bundled with installation and training services. Gensym also offers a Remote Software Support option, through which Gensym's support staff to view and interact with a customer's onsite Fermentation Expert installation. G2 operates under Windows NT or UNIX platforms and is priced according to configuration and functional options.

Several Heads are Better than One

With the new release of Fermentation Expert, Gensym hopes to offer a product that goes beyond the normal capabilities of expert system control software. Unlike many of its competitors, G2 Fermentation Expert does not rely on only one artificial intelligence engine: The program uses among fuzzy logic, neural networks, and rule-based reasoning together to arrive at the optimal model.

"One [artificial intelligence] tool alone will not solve all the sub-problems you encounter with fermentation," says Gensym pharmaceutical business development manager Bonnie Haferkamp. "Most control software on the market relies on one neural network architecture, but with a batch process as complex as fermentation it's advantageous to be able to choose your neural network architecture, as well as to benefit from fuzzy logic and rule-based reasoning."

Gensym prides itself on working closely with pharmaceutical industry customers, a practice which resulted in identifying fermentation control as a critical component of drug development programs. Gensym's software has been used by 18 of the world's 20 largest pharmaceutical companies for a variety of advanced applications, including the modeling and control of manufacturing processes. According to Gensym, customers enjoy a return on investment for fermentation applications of less than one year.

G2 Fermentation Expert is currently being used by four pharmaceutical companies, with "many more" companies evaluating the product, according to Haferkamp.

For more information: Bonnie Haferkamp, Business Development Manager, Pharmaceuticals, Gensym Corp., 25 Northwest Point, Suite 500, Elk Grove Villiage, IL 60007. Tel: 847-593-7820. Fax: 847-593-7835.

By Angelo DePalma with Alan S. Brown