New Cartridge Check Valve Solves Mounting Problems

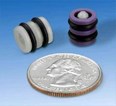

Morgan Hill, CA - Smart Products, Inc. recently introduced its new 132 Side Seal Cartridge Check Valve. Used in liquid and air applications, this micro check valve solves the mounting problems typically associated with traditional check valves.

Morgan Hill, CA - Smart Products, Inc. recently introduced its new 132 Side Seal Cartridge Check Valve. Used in liquid and air applications, this micro check valve solves the mounting problems typically associated with traditional check valves.

Incorporating a cylinder-shaped design with external sealing o-rings, the 132 Side Seal Cartridge Check Valve offers users convenient mounting options for manifolds, assemblies, or passages. The 132 Check Valve fits any 3/8" I.D. (inner diameter) hole -- whether drilled, milled, or molded. The double external o-rings ensure a positive seal, eliminating the distortion typically caused by press fitting valves.

Available in a choice of materials and a range of opening pressures from 0.10 to 20 PSI, the 132 Side Seal Cartridge Check Valve delivers a water flow rate of 1.7 LPM at 5 PSI.

The valve is used for various applications across a wide range of industries including medical, food and beverage, water treatment, ink manufacturing, automotive, marine, or any application requiring a manifold or panel-mounted check valve.

Smart Products cartridge check valves provide accurate, reliable control of fluid or gas in low pressure, low flow OEM systems and are often a cost effective alternative to metal valves, which are subject to corrosion. The valves feature a low inertia poppet design and double-tapered o-ring seats for a fast, positive seal.

SOURCE: Smart Products, Inc.