Prolonging Process Plant Life And Productivity With Resistive Coatings

A new process, InnerArmor, from a Wallwork Group company, Tecvac, is able to extend the service life and effectiveness of pipework, pumps, valves and other hollow process vessels

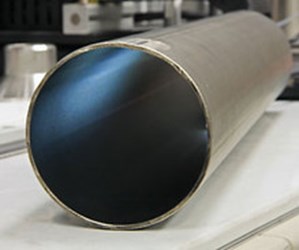

A new process, InnerArmor, from aWallwork Group company, Tecvac, is able to extend the service life and effectiveness of pipework, pumps, valves and other hollow process vessels. These can be can be severely affected by corrosion, erosion, fouling and wear, particularly in oil and gas exploration and production, downstream petrochemical processing, in chemical plants, and water industries where downtime can be very disruptive and expensive. Using the technique of plasma enhanced chemical vapour deposition (PECVD), Tecvac apply even, pin-hole free, thin films of highly resistive materials such as diamond like carbon (DLC), titanium carbide and other resilient materials.

Alternative approaches, such as the application of conventional metal coatings to internal surfaces can be difficult, especially in long lengths of pipe or plant with complex geometry. Similarly, fabricating pipes and plant from exotic metals and alloys that have strong resistance is expensive and operationally disruptive when these metals are not readily available.

The company is able to fine tune the coating to optimise characteristics such as hardness, wear and erosion resistance to abrasive solids such as sand and grit, or chemical resistance to acids, salts and hydrogen sulphide. Applicable to mild steel and other common metals, coatings typically vary from 30 to 80 microns.

InnerArmor coatings may be applied as single layer, but commonly a multi-layer, multi-material film will be applied to optimise performance. Stronger and subject to less stress than single layer coatings of the same thickness, multi-layer coatings have longer service life to maximise plant uptime.

The InnerArmor PECVD method uses the pipe or process vessel as the reaction cell. Insulated collars link the vessel to positively charged anodes via which the source gas is pumped at a prescribed pressure and temperature. Ionisation of the gas results in even deposition of the coating on the inner surface. Process cycles determine the overall depth of the finished film. In addition to protecting the pipe from attrition by the contents, the technique also protects pipe contents from contamination by failing pipe material so preserving product quality and value.

Operating under licence from InnerArmor developers Sub-One Technology of California, Tecvac share world-wide technical applications experience. Pump and piston chambers and other complex shapes can be coated effectively as well as pipe lengths of up to three metres. Environmentally benign, the PECVD process produces no harmful waste streams or volatile solvents and has a low carbon footprint due to a relatively low energy input.

InnerArmer is just one of a range of processes available from Tecvac and the Wallwork Group. As surface treatment specialists the company can apply processes that improve hardness and resistance, and that improve natural surface lubrication. These extend the working life of components in harsh environments and improve plant efficiency while lowering overall life-time costs. The company provide service to clients in demanding fields such as aerospace, energy, nuclear, motorsport and medical devices. Service is backed by extensive research and development capability to optimise processes before scaling up for full production.

Source: Wallwork Group company, Tecvac,