Special Promotion On StoneAge Bundle Blaster Portable Shell Side Heat Exchanger Cleaning Systems For Fall Turnaround Season

The Bundle Blaster shell side cleaning system from StoneAge offers a powerful and affordable automated solution for external cleaning of heat exchangers and tube bundles. This system is ideal for contractors and plants interested in low maintenance, cost-effective, easy to use equipment.

Durango, CO (PRWEB) - Industrial cleaning contractors regularly faced with difficult applications in the field know that challenge drives innovation. They must deliver results that are productive and cost-efficient, restoring revenue producing equipment back online at maximum capacity – quickly and safely. The right tooling and equipment is key to achieving effective solutions for a successful turnaround.

Cleaning large tube bundles, such as those found in industrial heat exchangers and evaporators, is one such application where opportunities for improved safety and efficiency have been recognized. Traditional methods of external bundle cleaning fall along the opposite extremes of dangerous manual shotgun blasting or expensive robotic trailer-mounted systems. To better meet the demands of these types of jobs, environmental services leader Veoliapresented StoneAge with a design challenge to build an automated system for high pressure water jetting heat exchangers in a wash bay environment. “We asked StoneAge to design a fully automated system that removed operators from high-risk activities, improved productivity, and increased mobility while demonstrating financial savings by reducing down time,” stated Andrew Dobson, Regional Business Manager with Veolia's UK industrial services operation.

Building on industry-proven Blastrack™ drive and rail technology, StoneAge answered Veolia’s challenge with the Bundle Blaster, a portable yet powerful automated system engineered specifically for external heat exchanger cleaning. “When designing the Bundle Blaster we had several goals: maximum cleaning power, long-term durability, easy portability, and affordable price,” described Jeff Hensley, Product Manager at StoneAge. “The Bundle Blaster was designed to be heavy-duty enough for industrial cleaning applications, yet it only costs a quarter to a third as much as other tube bundle cleaners.”

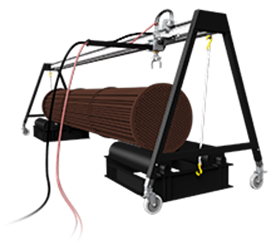

The Bundle Blaster system consists of a rotary package with a cleaning head that’s driven back and forth along a slotted rail supported by a sturdy, adjustable frame. A bundle is set on hydraulic rollers beneath the rail and is rotated as the cleaning head makes its passes from above. The rotary package can handle anywhere from 2,000 to 40,000 psi and up to 110 gallons of flow. There are several head options available with one to four jets. Fewer jets provide more hard-hitting power, while more jets deliver a wider cleaning path. The basic simplicity of this modular design allows for easy transport, setup and maneuverability at the job site yet the Bundle Blaster is strong enough to easily withstand the 500 pounds of force that can be generated during shell side cleaning. Operation of the Bundle Blaster is controlled remotely, allowing the operator to remain safely outside of the blast zone while maintaining precise control over both the traverse speed of the tractor and the rotation speed of the head.

When asked if he could squeeze the work of a 10-day shutdown into 6 days, Shawn Barker, owner and operator ofShawn Barker Construction in Trona, CA, rented two Bundle Blaster units from the FS Solutions rental fleet. The operation – cleaning 16 tube bundles measuring 25 feet in length and 5 feet in diameter – was completed in 5 days with less equipment than had been previously required. “These are more portable units,” Barker reported. “The setup time was a lot better and you can actually move them around a lot better. With the rollers, you can have one crane doing the work of two, because one crane usually has to just sit there and roll the bundles.”

“The Bundle Blaster has been within our business for 24 months,” attests Andrew Dobson of Veolia. “It has proven to meet the original design criteria and offers reliability and low maintenance providing minimum downtime to our clients. This equipment operates in the most difficult conditions predominantly on petrochemical refineries running consecutive shift patterns on time driven critical projects and performs consistently to a high standard without failure.”

StoneAge is offering a special promotion on the sale of Bundle Blaster shell side cleaning systems. Orders placed between August 1 and October 31, 2014 will receive free standard worldwide shipping (some restrictions apply – contact local StoneAge dealer for details). Visit the StoneAge waterblast tools website to learn more:http://www.stoneagetools.com/bundle-blaster.

Source: PRWeb

View original release here: http://www.prweb.com/releases/2014/08/prweb12077268.htm